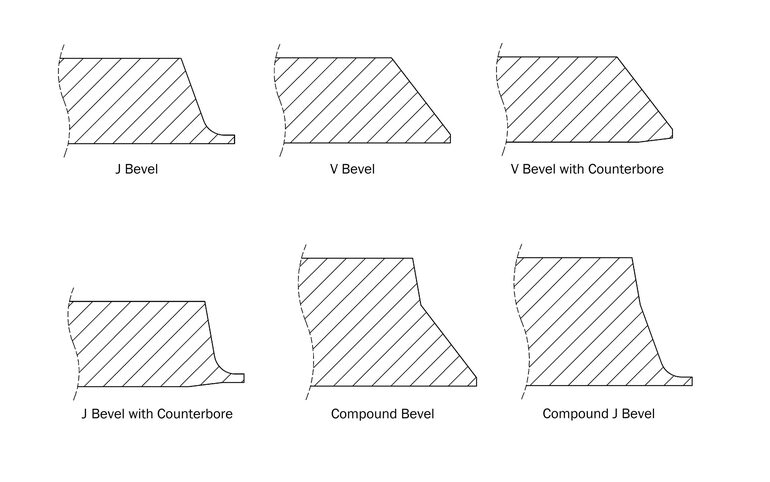

Bevel Shapes for Pipe Beveling

To weld a pipe with a wall thickness of more than 3mm, a bevel must be carried out at one or two edges of the pipe, so they fit better. There are various shapes of pipe bevels and the decision of the shape to be applied to a pipe is depending on the pipe welding type and welding process.

The most common bevel shapes are the V-shape bevel (also known as V groove, or plain bevel) and the compound V-bevel (also known as double V groove). The bevel angles in V shape can be carried out in mainly 30, 37.5, and 45 °. Most V-bevels have land which most of the time is a straight 90 degrees part between 1 mm and 1.8 mm high. V and compound V-bevel are commonly used in the automated and manual pipe welding process.

The other common bevel shape is the J-bevel, J-prep or so-called tulip bevel is a weld end preparation with the shape of a J. With a J-shape, a small amount of material is removed during machining, and a low volume of welding material and wire is needed for the welding process. The name of this welding method is narrow gap welding which can be used in manual or automatic welding processes. J-prep can be performed on both heavy and light-walled pipes, whereas compound J-prep (also known as double J-bevel) can be applied on heavy-walled pipes only.

Another example of a bevel shape is the inside beveling, also known as the counterboring or back bevel. Pipe counterboring is lightly machining the inside of a pipe to ensure that the land is the same width over the whole circumference of the pipe end. The combination of the beveling angles is also commonly used such as compound J bevel with counterboring.

At Copier Machinery we have all the knowledge and engineering skills for different bevel shapes, that we have designed more than 350 tooling for different shapes and requirements. Also, our ID tracking chuck or ID tracking module is following the inner diameter of the pipe to keep track of the out-of-roundness and perform a bevel shape with tighter tolerances. We deliver both standard tooling and customized tooling to meet the exact requirements of our customers.

Contact us for advice on bevel shapes and pipe beveling machines.